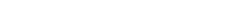

Machine features

1.The main machine and wire feeder are integrated. It has the characteristics of small size, long life and easy movement.2.The handheld welding and cutting machine uses an intelligent welding and cutting head, which can flexibly deal with various objects and angles.

3.The cooling system adopts air cooling, which is stable and reliable, with low failure rate and high efficiency and energy saving.

4.The wire feeding machine adopts graphene wire feeding hose, which makes wire feeding smoother.

5.The whole machine is light and portable, which can meet the needs of mobile welding.

Technical parameters

| Machine dimensions | 740*425*610mm |

| Machine net weight | 60kg |

| Cable length | 5 meters |

| Auto feeding loading | ≤15kgs |

| Cooling mode | Air-cooling |

| Power input | 1-phase 220V, or 48V mobile power (48/100Ah mobile power can run the machine for 1 hour) |

| Total power consumption | 6kwh (when full loaded) |

| Advantages | 1. Welding, cutting, cleaning 3 functions 2. Highly integrated, wire feeder built in machine cabinet 3. Two types power supply: 1-phase AC 220V, or 48V mobile power |

| Laser source power | 1500W |

| Welding system | Qilin-LaserMen |

| Welding gun weight | 0.6kg |

| Welding gun connection | Type-C connection |

| Welding modes | Dot, line |

| Working modes | Welding: wobble, welding width 5mm Cutting Weld bead cleaning: width 5mm Cleaning: width 40mm (optional) |

| Languages | 23 languages optional |

| Protective lens | 2 pieces, drawer type |

| Focal lens | drawer type |

| Collimator lens | drawer type |

Video

Machine details

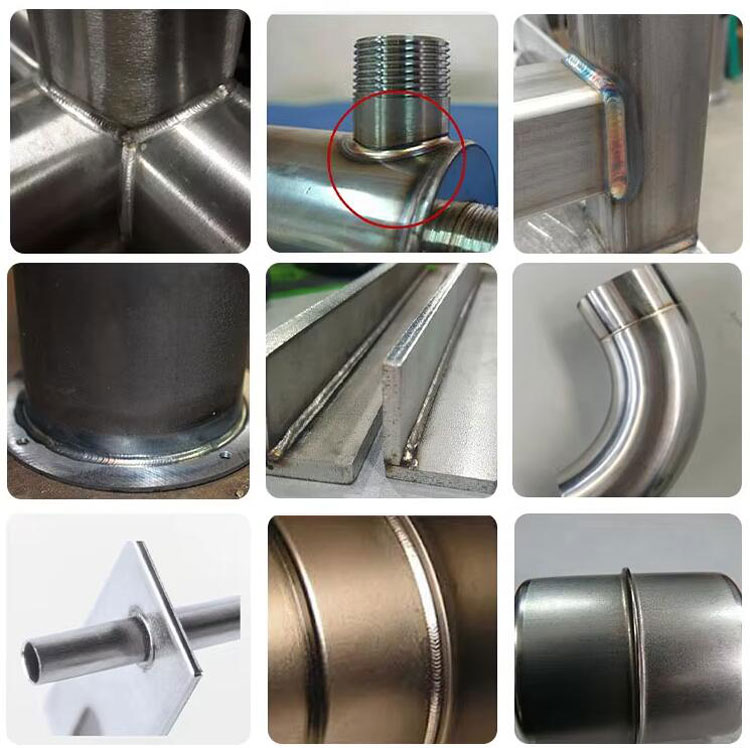

Machine Application

Main ApplicationThe handheld welding machine is mainly used for laser welding of long-distance and large workpieces, overcoming the travel space limitation of the worktable.

The heat-affected area during welding is small, which will not cause problems such as deformation, blackening, and marks on the back of the workpieces.

Moreover, the welding depth is large, the welding is firm, and the melting is sufficient.

This machine can not only realize thermal conduction welding, but also continuous deep melting welding, spot welding, butt welding, lap welding, sealing welding, seam welding, etc.

Application industries

Widely used in aerospace, shipbuilding, instruments, machinery, electronic products, automobiles, kitchenware and other industries.

Automobile and accessories industry, motorcycle and accessories industry, agricultural machinery industry, engineering machinery industry, construction machinery industry, two-wheeled and three-wheeled vehicle fitness equipment industry, pressure vessel industry, new energy vehicle industry, hardware industry, etc.

This machine can also be used for precision welding of metal materials, especially in the 3C industry.

Used in the advertising industry, welding and forming of metal characters, lighting and mold industry, optoelectronic communication devices, medical, electronics, copper parts, aluminum parts and small welding processing industries.